Complete the form to request product details, pricing, schedule a demo, or to discuss an upcoming project.

In the early days, 3vG was a handful of people, mostly working on government-funded projects for the Canadian Space Agency and the odd commercial project. InSAR was the dark side of remote sensing. Few knew about it. Data was expensive and scarce, and most work was firmly rooted in academia.

Freeport-McMoRan changed all of that. As a very forward-thinking mining company, Freeport-McMoRan issued a call for InSAR monitoring proposals for all of their sites. In 2014, InSAR companies like ourselves hadn’t really encountered the words InSAR and monitoring in the same phrase before, let alone understood the requirements of regular, short latency, easy-to-understand reports. InSAR reports to us were dense and complex, with turnaround times on the order of weeks or months. And there was admittedly little to no attention paid to InSAR ‘products’.

InSAR for mining was also not well-tested. The technology of the day was called Persistent or Permanent Scatterer InSAR, which did not suit the dynamic mining environment, where often half of the measurable points were decidedly non-persistent. A new approach would be needed that could tolerate high levels of surface disturbance from blasting and dumping.

During the RFP, Freeport-McMoRan issued a specific challenge; what can you give us within 24 hours? This was, to our ears, an insanely short amount of time. InSAR processing is a many-step procedure, requiring significant compute power. Back then, some algorithms alone took longer than 24 hours.

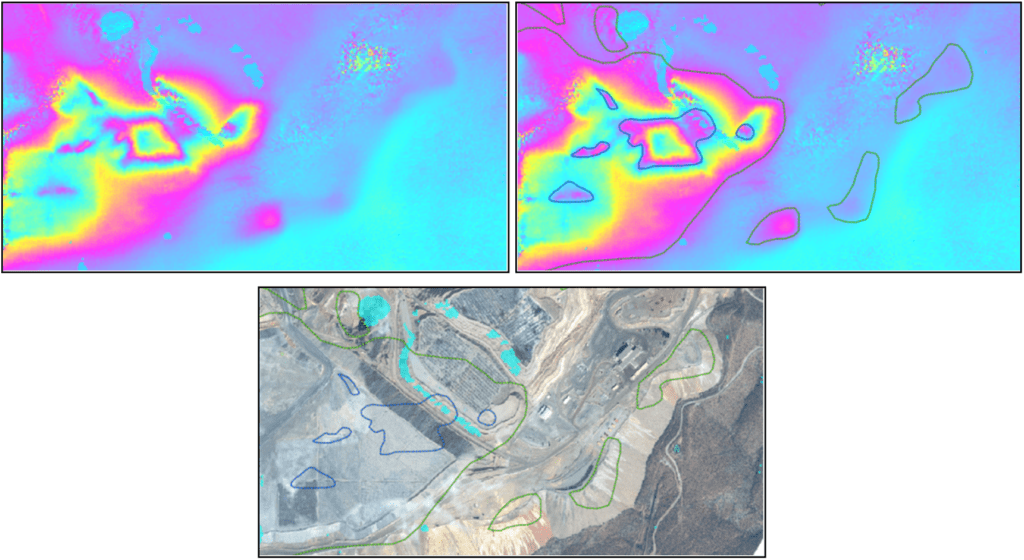

After consideration, we realized that we could reconfigure InSAR processing to work on a much shorter period of data. This is, afterall, what mine geotechs are interested in; what has changed recently? We also had to talk to our data provider, it turned out they too were not really prioritizing data latency. We could also skip many processing steps, in favour of highly-trained human analysis of intermediate outputs. The figure below shows how this worked. Phase difference images called interferograms are sensitive to displacement over some period. Human interpreters can use these to draw displacement contours. To our advantage, mining displacement tended to be high, overwhelming many other unwanted contributions to the data.

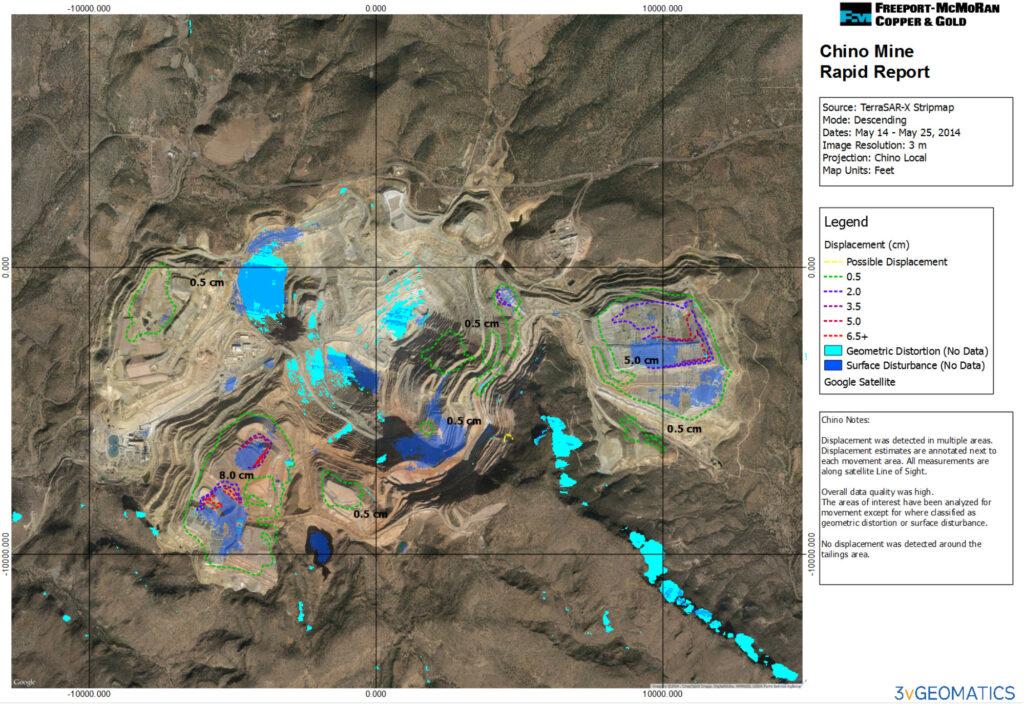

Lastly, we needed a product. Working mine geotechs are managing day-to-day risks. They don’t have time to wade through reams of text and charts. Instead, we converged on a simple snapshot of displacement on a map, covering the most recent period, with some brief notes when needed.

Rapid Report #1 was delivered on May 25, 2014, covering Chino mine in New Mexico. Despite plenty of testing, we were in some sense building the plane as we were flying it. The first report did not go smoothly. Three people were ironing out various issues with the processing chain and product until after midnight. By the end of it though, we had kept our promise and we managed to deliver within the 24-hour deadline. The figure below shows the first-ever Rapid Report.

The Rapid Report was soon in high demand. Dozens of Rapid Reports per month were flying out the door, and word really started to penetrate the mining Industry about InSAR. InSAR gradually switched from a nice to have to a must have for mining. For a couple of years, there was no real competition in the monitoring space and the company grew to several times its size, building on the success of the Rapid Report. Once word eventually got out, all of the major InSAR providers began to offer some flavour of the original Rapid Report.

We’re happy to say that we’re still with Freeport, 2024 marks our tenth anniversary. Freeport-McMoRan continues to demand the best, constantly driving forward innovation at 3vG. The many changes and advances over the years are too numerous to list, but here are some highlights.

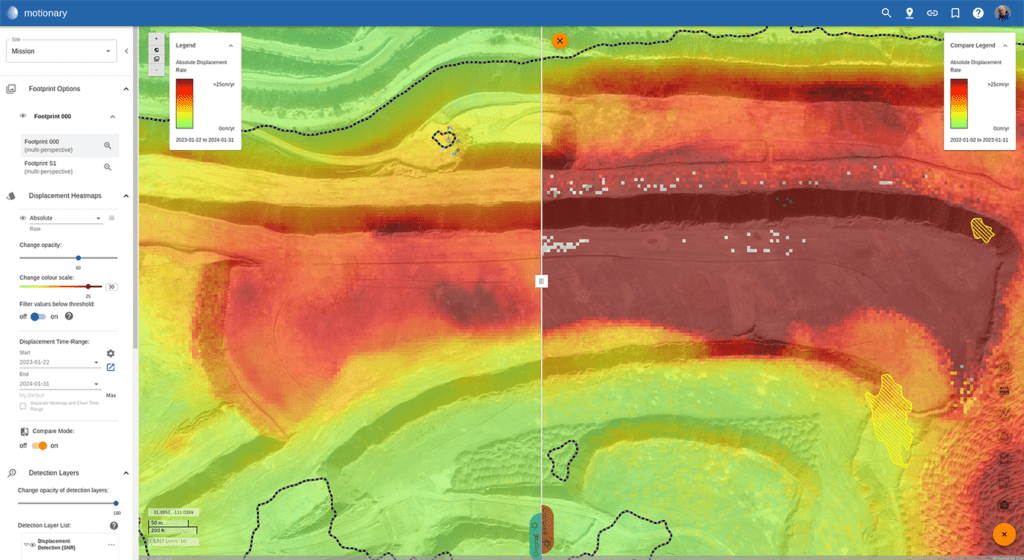

Following many improvements to hardware and algorithms, 3vG have since built Displacement DataStream incorporating full-blown time series based displacement results on a rapidly updating basis. Results can be delivered to suit the user, but commonly our browser-based data delivery platform Motionary is used.

Rapid Reports still play a part. They are now automatically generated and delivered with Displacement DataStream email updates. This often suits the busy mine geotech that just needs a quick update on a phone, rather than a detailed analysis on a PC. There have been a number of other changes over the past years: